Production process

1. Wet paddy

.Wet paddies are bought from farmers and transported to our factory for processing. Annual volume of 240,000 ton

2. Drying

3. Dehusk

4. Milling

5. Polishing

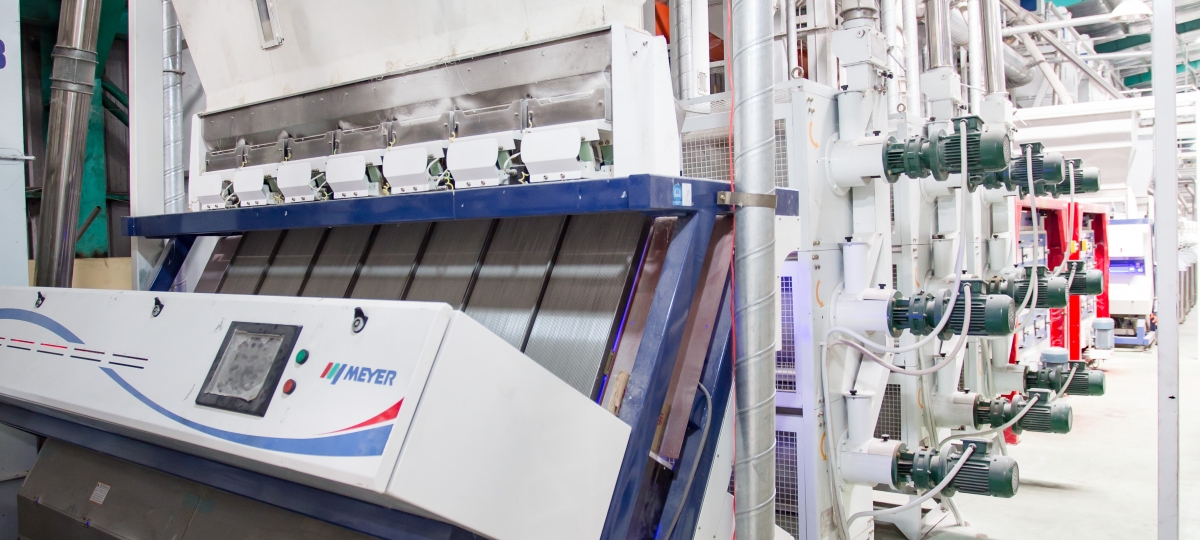

6. Sorting

7. Packaging

Packing process

Reliable OEM Rice Packing

Trusted by global partners for large-scale OEM supply, Cam Rice delivers consistent quality and high-volume rice exports.

-

Flexible bag materials: Woven PP, PAPE, or BOPP available to meet each client’s specifications.

-

Custom pack sizes: From 1 kg to 50 kg, with vacuum-sealed options for small packs to extend freshness and prevent pests.

-

Fully enclosed process: Rice packing and container loading are carried out in a sealed environment to ensure top food-safety and hygiene standards.

-

High daily output: Packing capacity of up to 1,000 tons per day, ready to meet demanding export schedules.

Cold storage

In 2018, Cam Rice invested more than 12 billion VND to build one of Vietnam’s very first cool storage facilities dedicated to rice - a forward-looking step to secure premium quality from harvest to export.

Covering over 2,000 m², this temperature-controlled system can store up to 6,000 tons of rice under stable, monitored conditions. By maintaining optimal humidity and temperature, the facility protects each grain from oxidation, pests, and aroma loss, ensuring that the rice retains its natural fragrance, fresh texture, and nutrient profile over time.

This investment reflects Cam Rice’s long-term commitment to move Vietnamese rice beyond volume and toward world-class quality. Cool storage is not just a warehouse - it is the backbone of building high-end rice brands that meet the strictest global standards and deliver consistent value to partners around the world.